PROPER HANDLING OF GRAIN TO REDUCE POST HARVEST LOSS

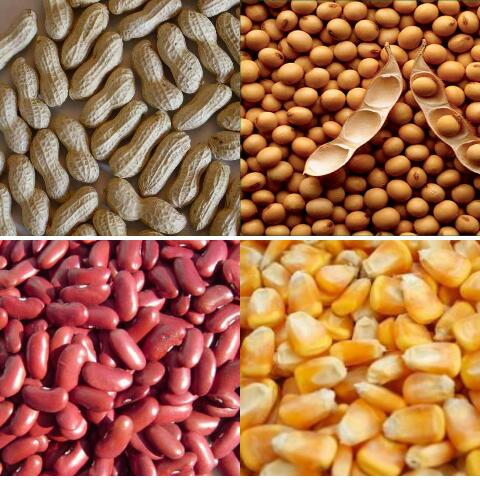

Grains are small, hard and dry seed fruits of grass or pea family with or without attached fruit layers having the fruit and the seed wall united together for human and animal consumption

Classification of grains

1. CEREAL (grass, monocotyledon, carbohydrate, starch)

- Warm season grains include millet, maize, sorghum etc

- Dry season grains include rice, oats, barley etc

2. LEGUMES (Pea family, dycotylidon, protein)

- Oil Seeds include Soya bean, groundnuts etc

- Non oil seeds include ordinary beans (MEDINO, FONCHA etc haha Cameroonians get), Peanuts, Pea etc

Grain Harvesting

Gathering a ripe crop from the field which mark the end of growing seasons by using hands, stickler, reaper or combined harvesters in cases of mechanized farming.

Grain Plant stages

Sugar in the stem and leaves is translocated to the grain fruit and converted to starch, green plant to yellow plant. The grain is then formed and moves from a sac of clear liquid to milky to soft and hard dough and then to real hard dough.

Grain Drying

This is the systematic removal of moisture from the grain. Africans and Cameroonians in particular have two basic drying habbits. The natural drying habit ( sun, wind, solar tents, dryers etc) and the Artificial Drying (in-bin, batch and continues flow dryers.

The maximum recommended temperature for drying depends on the final use of the grain. If the end use is seed then recommended temperature is 500 C, while grain for milling or grinding should not be more than 750 C. Reduction in nutritional value occurs when the grain temperature hits 900 C and above.

Grains should be cooled after drying operations before threshing (peeling as is known locally) and winnowing

Pre Storage Conditions for Grain

Before you attempt to store grains first check for the following

- Grain must be dried and cooled to the safe moisture content to limit mould growth and insect infestation which are the main sources of grain spoilage during storage.

- Grains should be cleaned propally to remove impurities. Grain with a lot of impurities habour higher insects etc

- Grain storage structuresand the sorroundings must be inspected and kept clean and every necessary repairs done before the receipt of grain.

Factors affecting Storage of grain

- Grain Moisture

- Initial Insect and pest infestation level and the type of insects and pests

- Storage environment

- Initial storage mould infestation

- Sanitation

- Grain quality

Grain Storage Levels

- Farm Storage Level: Using two popular methods of crib and rhumbu ( call it banda in Cameroon local languages)

- Domestic Storage Level: Using cans, tins and Hermetic structures

- Commercial Storage Level: Warehousing and advance storage units

- Strategic Storage Levels: Using multiple silos which are preferably cylindrical in structure and made of concrete, steel or aluminium materials.

The Purdue University, West Lafayette, Indiana USA has developed two acronyms for grain storage

D-I-C-E,

- D- Dry grain before bagging,

- I- Inspect warehouse or structure before storing grain,

- C- Clean warehouse and surrounding regularly and

- E- Examine grains regularly

S-L-A-M,

- S- Sanitation,

- L- Loading,

- A- Aeration,

- M- Monitoring

Summary Of Post-Harvest Grain Processing

- HARVESTING

- SHELLING OR THRESHING

- DRYING AND COOLING

- CLEANING AND SORTING

- BAGGING, HERMATIC SILO, AND STORAGE.